IZI PVD Coatings

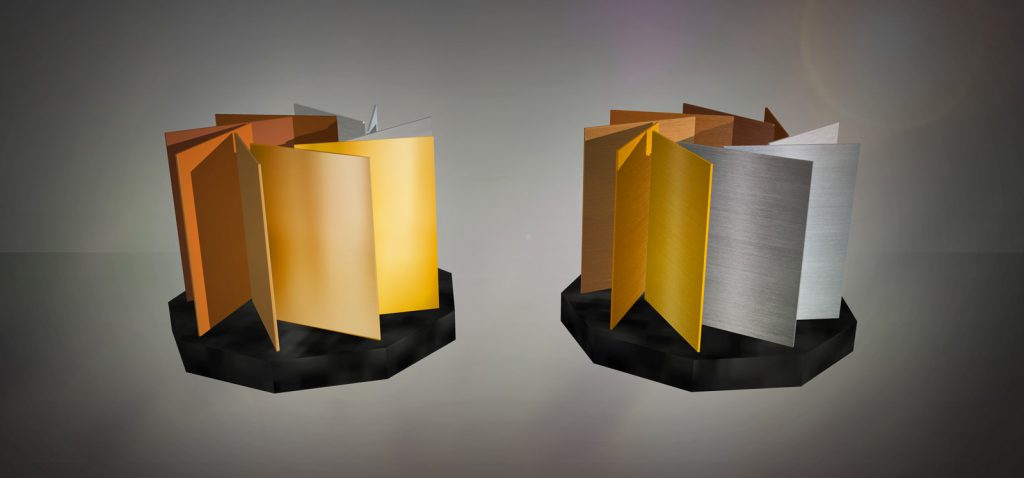

We provide 2 different sample boxes, Glossy & brushed box.

We provide 2 different sample boxes, Glossy & brushed box.

Physical Vapor Deposition (PVD) coating has found a multitude of new uses since it was first discovered.

PVD is also known as thin-film coating, is a process in which a solid material is vaporized in a vacuum chamber and deposited onto the surface of a part. These coatings are not simply metal layers though.

Instead, compound materials are deposited atom by atom, forming a thin, bonded, metal or metal-ceramic surface layer that greatly improves the appearance, durability, and/or function of a product.

PVD is the most environmental friendly and nonpolluting process of metal surface finishing nowadays. Let us protect our planet by choosing Physical Vapor Deposition. The PVD technology has absolutely no environmental impact: during the processing phases there are no releases of any kind in the atmosphere.

PVD coatings are non-toxic and hypoallergenic and have no migration of irritating substances to human health.

Based on the combination of time, heat, metal and inert gas such as nitrogen, oxygen, or methane, you can create a specific color and treated surface thickness.

A cost-saving treatment that gives an identical impression of real brass, bronze, copper, Chocolate, Champagne, Gunmetal, Rose Gold, Cobalt Blue, Royal Gold and many more different colors. It will help to maintain an exclusive product for a long time.

Matte and brushed metal finishes also receive PVD to lock in these desired physical appearances for a lifetime of corrosion, chemical, and scratch resistance.

In addition to the appealing look of PVD, an anti-fingerprint coating (AF) can be added to the process. This makes it particularly desirable in high-touch-point areas. Most anti-fingerprint applications are a coating to impart the characteristic, usually a spray.

The problem with most of these is that they can wear quickly. When we do it in chamber, simultaneous to the color, the AF becomes part of that surface, So the anti-fingerprint characteristic will last far longer than the traditional spray coating.

PVD AF can also be found in appliances, and other aesthetic surfaces that need to be cleaned easily. When PVD AF is applied to building exteriors, the surface actually helps self-clean whenever it rains.

Superior quality that will outlast any traditional finish

PVD can also be used on lower-cost or lighter weight base materials (including plastic and aluminium) and provide superior aesthetic looks, abrasion, and corrosion resistance.

Another technical advantage of PVD is the ability to recreate the appearance of more costly metals such as copper, brass, bronze, and gold.

PVD coated metal will not patina. You only need simple cleaning to keep the original color looking good.

We ship our PVD Sample Box free of charge world wide. No fees, no shipping. Just fill out the form bellow and the box will be on it's way to you.